high quality dredge pump supplier

Latest articles

WZ series slurry pumps are new type wear resistant & corrosion resistant slurry pump for the complexity and specificity of coal, power plant, metallurgy, chemical, building materials and other industries.

high quality dredge pump supplier...

high quality dredge pump supplier 【high quality dredge pump supplier】

Read MoreIs the discharge configuration suitable for abrasive slurries?

high quality dredge pump supplier...

high quality dredge pump supplier 【high quality dredge pump supplier】

Read MoreSeries of TL >FGD pump is a single stage single suction horizontal centrifugal pump. It is mainly used as the circulation pump for absorbent tower in FGD applications. It has such features: wide range flowing capacity, high efficiency, high saving power. This series of pump is matched by tight structure X bracket which can save much space. Meanwhile our company develops many kinds of material targeted on the pumps for FGD.

high quality dredge pump supplier...

high quality dredge pump supplier 【high quality dredge pump supplier】

Read MoreFind a professional slurry pump supplier

high quality dredge pump supplier...

high quality dredge pump supplier 【high quality dredge pump supplier】

Read MoreOne problem with centrifugal pumps is that the velocity and shear forces within the pump may damage the slurry/solids. Typically, twin-screw pumps cause the least damage to solids in the slurry.

high quality dredge pump supplier...

high quality dredge pump supplier 【high quality dredge pump supplier】

Read MoreThe terms slurry pump and dredge pump can be used interchangeably.

high quality dredge pump supplier...

high quality dredge pump supplier 【high quality dredge pump supplier】

Read MoreWorking principle

high quality dredge pump supplier...

high quality dredge pump supplier 【high quality dredge pump supplier】

Read MoreDespite the complexity of internal flow patterns, the overall performance of dredge pumps is predictable.

high quality dredge pump supplier...

high quality dredge pump supplier 【high quality dredge pump supplier】

Read MoreFor more information about this new and improved pump, please contact us.

high quality dredge pump supplier...

high quality dredge pump supplier 【high quality dredge pump supplier】

Read More>Slurry Pump

high quality dredge pump supplier...

high quality dredge pump supplier 【high quality dredge pump supplier】

Read More

Popular articles

- Adapting a pump to its precise application - be it pulp and paper, gas and oil, mining or industrial applications - will have a direct impact on its service life. That's why our bespoke pumps have the unique advantage of interchangeable components. These components include slurry valves, which can be replaced every 6 months as a preventive measure and every 12 months for regular maintenance, depending on the application.

- The most important thing here is to determine the pump power required to deliver a specific fluid flow at the desired or required differential pressure. Consider the following.

- Dredge Pump

- The dredge pump is designed to draw sediment, debris and other hazardous materials from the surface layer into the suction pipe and transport the material through the pipe to the discharge site. The pump must be able to handle common solid debris of various sizes that can pass through the pump, thus minimizing the downtime required for cleaning.

- With the development of the dredging market, the requirements for dredging equipment are getting higher and higher, and the suction resistance and vacuum of dredging pumps are getting higher and higher, which has a great impact on the efficiency of dredging pumps and the chance of cavitation is getting higher and higher. The number of >dredging pumps is also increasing.

- Slurry Pump Impeller

Latest articles

-

Repairable - target=_blank title=Rubber Lined Slurry Pumps>Rubber lined slurry pumps can be repaired by simply replacing the bushing.

-

Keep in mind that slurry pumps are designed to adapt to specific pumping conditions. Pumps used in the cement industry handle most fine particles at low pressures, so the casing can be of lightweight construction. In rock pumping, the casing and impeller must be able to resist slamming, so they must be built thick and strong.

-

Why would maintenance personnel want to adjust a high-speed rotating impeller to a static lining component while the unit is running? Even if interlocking devices are used to prevent static and non-static components from coming into contact, how credible are these features and what are the implications for pump wear parts, bearings and motors if these two components come into contact?

-

There are three different >types of slurry pump impellers; open, closed, and semi-open. Each has its own strengths and weaknesses, depending on the application. Some are better for solids handling, others are better for high efficiency.

-

>Slurry pump impeller is one of the most important parts of centrifugal slurry pumps. Depending on the application, slurry pump impeller selection is crucial to slurry pump performance. Slurry applications can be especially hard on the impeller of slurry pumps because of their abrasive nature. In order slurry pumps operates efficiently and stand up to the test of time, impeller has to be selected properly for slurry pumps.

-

Advantages of rubber

Links

- Another challenge is meeting the growing demand for organic products worldwide. As consumers become more conscious about their health and the environment, there is an increasing demand for organic and sustainable products. This presents a great opportunity for exporters to tap into this market and differentiate themselves by offering high-quality, organic turmeric powder.

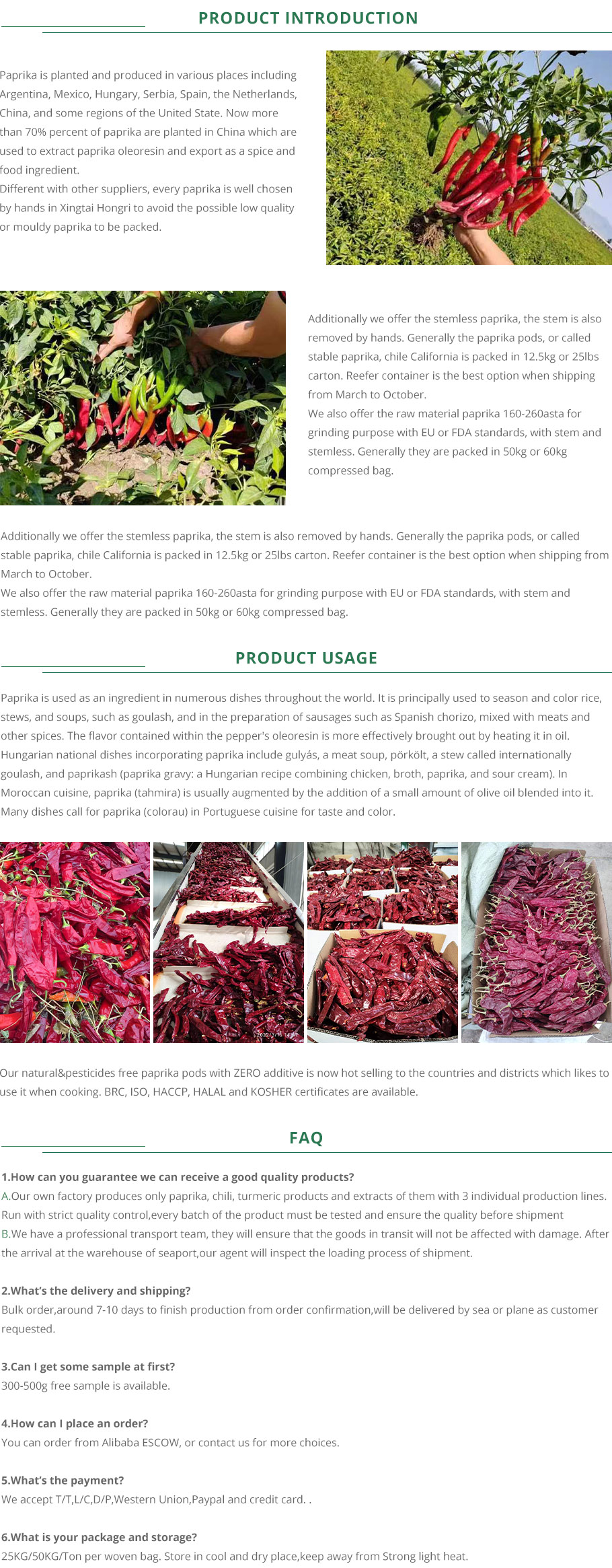

- These factories are the heart of the paprika production process, where the magic happens. The first step in this transformation begins with cultivation. Farmers meticulously tend to their pepper fields, ensuring optimal conditions for growth - ample sunlight, fertile soil, and timely irrigation. Once the peppers reach maturity, they are harvested, usually by hand, to preserve their integrity.

Guajillo peppers are second to jalapeno if we're talking about chilies used in Mexican dishes, but are also commonly used in Southwestern cuisine. Hence, their ground or powder form is among the best Hungarian paprika substitutes.

- Sweet paprika

- 6. Grinding The peeled roots are ground into a fine powder using modern machinery or traditional stone grinding methods.

In the vibrant palette of culinary spices, the color red takes a prominent spot—embodying both the allure and the promise of heat that can kick the flavor of any dish up a notch. Although these spices share a common color, their origins, taste profiles and uses in cooking are distinct, making each one an indispensable ingredient in its own right.

- One of the most well-known uses for red dried chiles is in Mexican cuisine. From spicy salsas to hearty stews, these peppers play a crucial role in creating the bold and vibrant flavors that characterize Mexican food. In dishes like mole sauce, the complex and rich flavor of dried chiles adds depth and intensity, creating a truly unforgettable taste experience.

Additionally, studies have indicated that regular consumption of cayenne pepper may have positive effects on blood sugar control, thus benefiting those with diabetes Additionally, studies have indicated that regular consumption of cayenne pepper may have positive effects on blood sugar control, thus benefiting those with diabetes

Additionally, studies have indicated that regular consumption of cayenne pepper may have positive effects on blood sugar control, thus benefiting those with diabetes Additionally, studies have indicated that regular consumption of cayenne pepper may have positive effects on blood sugar control, thus benefiting those with diabetes